Partial discharge measurement and monitoring system - IPD core

By detecting and monitoring partial discharges, the earliest signs of impending electrical equipment failure, this system enables proactive maintenance planning and helps prevent catastrophic events

Insulation is critical to every asset in power generation, transmission, and distribution. Typically, the lifespan of an asset is largely determined by the state of its insulation. Insulation failures can often lead to fires or explosions, causing substantial damage to primary equipment and surrounding structures. Such incidents result in high costs due to asset damage and decreased availability. Asset managers strive to minimize these risks and keep maintenance expenses as low as possible.

Partial discharges are the earliest indicators of insulation degradation or defects in transformers, generators, motors, and cables.

The principles guiding our solution

iPDCore is a unique solution for various types of equipment, fully compliant with IEC and IEEE standards. It features fully synchronous data acquisition, adjustable digital filters, and self-adjustable gain with 15 levels. The system enables automatic classification of partial discharges and offers a user-friendly experience through its intuitive interface.

Built on the robust, proprietary KonFID hardware platform developed in-house, iPDCore is designed for diagnostics and monitoring of all types of electrical power equipment, including transformers, cables, generators, and motors. Its cutting-edge processing algorithms ensure reliable measurement results and unparalleled real-time processing performance.

iPDCore is a fully digital system, characterized by a wide input range, extensive signal frequency bandwidth, and high-speed synchronous acquisition on all channels. The advanced DSync data processing algorithm ensures effective noise suppression and source separation of partial discharges.

The integration of advanced algorithms with the proprietary KonFID platform provides exceptional processing capabilities, allowing real-time processing of up to 2,000,000 pulses per second per channel.

DSync technology

DSync Technology is a core feature of iPDCore, designed to extract spectral components of partial discharge (PD) pulses while ensuring synchronization across all channels and parallel processing branches. This advanced technology leverages state-of-the-art algorithms derived from modern telecommunications systems.

DSync, short for Demodulator Synchronization, employs a state-of-the-art demodulator comprising components such as a low-pass filter and a frequency mixer. Each processing branch offers adjustable mixing frequency and bandwidth. These intuitive parameters ensure straightforward correlation with the IEC60270 standard:

Filter Cut-Off Frequency corresponds to the measurement bandwidth of the bandpass filter as described in IEC60270. Mixer Frequency matches the central frequency of the bandpass filter as outlined in IEC60270.

The DSync processing branch excels at suppressing out-of-band spectral noise, outperforming common digital or analog filters used by competitors. Its real-time processing capability, handling up to 2,000,000 pulses per second, ensures no PD pulses are missed, unlike some currently available devices. Outputs from each DSync branch can be used to present standard PD measurements, such as apparent charge, NQS, and Phase Resolved PD Pattern (PRPD) diagrams. By leveraging outputs from simultaneously processed DSync branches, multidimensional clusters can be formed for effective noise suppression and PD source separation.

DSync Clustering

For single-channel measurements, clusters are formed using multiple parallel DSync branches, with each branch extracting spectral components from different segments of the spectrum. This configuration is known as a DSync Demodulator Cluster. For multi-channel measurements, additional cluster space is created by using DSync branches with identical processing settings across all channels, referred to as a DSync Multi-Channel Cluster.

DSync Demodulator Clusters

Each PD pulse or noise can be identified by its spectral signature. By conducting simultaneous measurements across different parts of the spectrum, noise and various PD sources can be clustered and subsequently separated and/or suppressed.

DSync Demodulator Clusters leverage this capability, providing a valuable tool for reliable PD measurements. For visualization, outputs from different DSync branches are vector summed, with the angles between consecutive branches equal to 360°/N, where N represents the total number of DSync branches.

*Note: Demodulator cluster technology is not available in the USA, UK, Germany, Austria, Switzerland, Italy, and Liechtenstein.

DSync Multi-Channel Clusters

In three-phase power transformers or a bank of single-phase transformers, partial discharges originating from a single winding can be detected across all channels/phases. The acquired PD input signal will be stronger on the channel/phase closer to the PD source and attenuated on channels/phases further from the source.

Considering this, DSync multi-channel clusters are formed to effectively suppress noise or isolate PD sources. This algorithm is also applicable to generators and cables, or any system with measurements across all phases of a three-phase setup.

Regardless of the clustering or noise suppression tools used, iPDCore processes them in real time, providing exceptional response and measurement accuracy.

Automatic noise suppression and source separation

The clustering technology mentioned above offers an outstanding tool for noise suppression and source separation. However, in monitoring devices, the selection and application of clustering technology must be automated.

While cluster selection can be performed manually when using iPDCore as a laboratory or portable instrument, iPDCore also features automatic clustering technology using the latest machine learning algorithms. The PRPD (Phase-Resolved Partial Discharge) diagrams generated through clustering are automatically classified to determine the type of fault in the equipment.

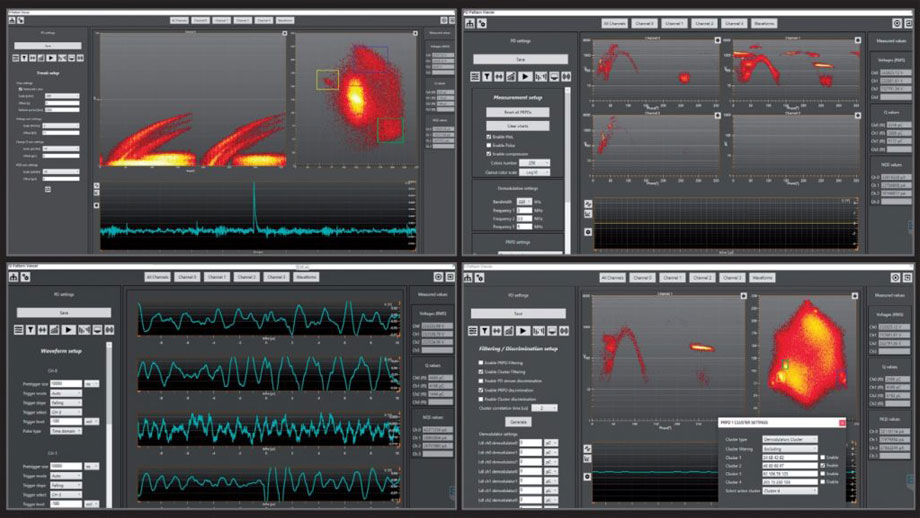

Intuitive configuration and visualization using iPDViewer

Real-time data processing combined with high-speed connectivity interfaces ensures smooth and clear visualization of PD measurements. Each device is equipped with a Gigabit Ethernet interface and an optional Wi-Fi interface. High-resolution PRPD patterns or clusters are generated simultaneously for all channels at a very high frame rate.

Extension Modules for complete monitoring or laboratory automation solution

iPDCore can easily be upgraded with voltage/current, RTD, or digital input and output modules to create a comprehensive monitoring solution for any type of electrical power equipment or to automate laboratory measurements. It is an integral part of the Končar TMS transformer monitoring system and the Končar MCM rotating machines monitoring system. iPDCore is also successfully implemented as a platform for laboratory measurement automation.