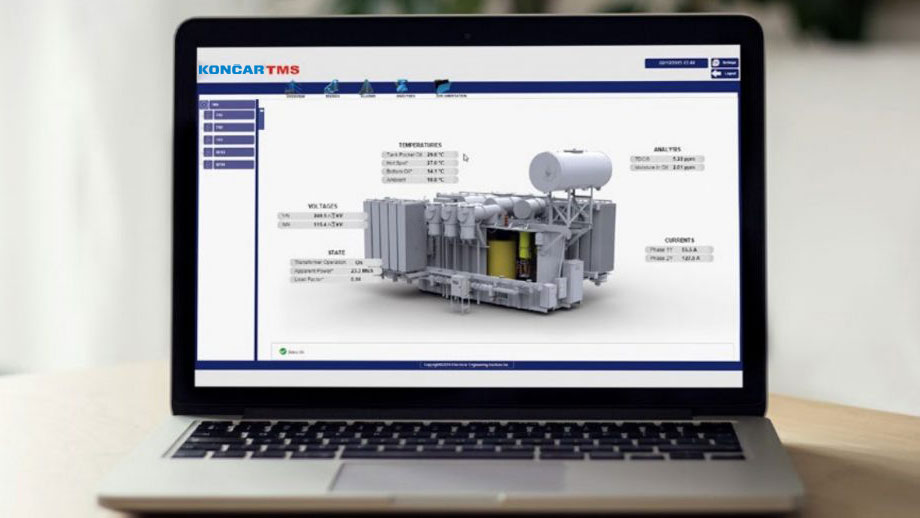

Transformer monitoring system

Transformers are vital and highly valuable components in power systems. Equipping them with an online monitoring system is crucial for effective information gathering, condition assessment, management, and decision-making.

KONČAR TMS incorporates decades of experience in transformer design, production, and on-site diagnostics, combined with a proven hardware platform, to offer a state-of-the-art monitoring and diagnostic system.

KONČAR TMS incorporates decades of experience in transformer design, production, and on-site diagnostics, combined with a proven hardware platform, to offer a state-of-the-art monitoring and diagnostic system.

KONČAR TMS offers a comprehensive online monitoring system for all types of power transformers and shunt reactors. The system features modular and expandable design, suitable for both new installations and retrofitting existing transformers, regardless of manufacturer. It facilitates the monitoring and diagnostics for all critical transformer components by integrating available sensors and supporting various IED communication protocols. TMS features advanced models for transformer condition assessment (conductors, thermal model, insulation aging, cooling efficiency, tap changer), sophisticated trend analysis tools, and the capability to interpret gas analysis results from transformer oil according to current IEC and IEEE standards. Additionally, key features of the system include user-defined alarm limits and gradient settings, long-term data storage and event tracking, automatic report generation (periodic, event-based, and on-demand), and various remote access options.

Benefits and features of the monitoring system

The primary advantages of the KONČAR TMS include the detection of incipient faults and the prevention or mitigation of failures and unplanned outages. The system supports condition-based maintenance, enhances personnel safety, improves environmental protection, and provides valuable data for analysis in the event of a failure. Additionally, the TMS facilitates the optimization and better management of transformers (such as overloading and residual life assessment) and enables their integration into a 'Smart Grid.'

Due to its modular design, the system can include any of the following functions:

- Bushings

- Active Part

- Partial Discharges

- On-Load Tap Changer

The system's tools enable trend analysis, alarm and event logging, temperature forecasting under overload conditions, data export to text and Microsoft Excel, and automatic report generation.

System architecture

The Končar TMS is built on the KonFID processing platform, which is specifically designed for monitoring, control, and diagnostics of primary equipment in power generation, distribution, and transmission. The platform offers a broad selection of I/O modules and accessories, making it versatile for any application, including high-end partial discharge monitoring and transient voltage recording. The main processing module features a multi-core ARM processor with FPGA. It supports one USB 2.0 interface, two 100 Mb Ethernet interfaces, one 1 Gb Ethernet interface, and an SD card slot for data storage. KonFID can be easily upgraded with voltage/current, RTD, or digital input/output modules to create a complete monitoring and automation solution for any type of asset.

Monitoring transformer bushings

KONČAR TMS provides real-time insight into the condition of bushing insulation while the transformer is in operation. Developing faults within the bushings can be detected at an early stage, allowing for timely actions to safeguard substation equipment and personnel.

A robust digital signal processor module enables precise measurement of the amplitude and phase angle of leakage current through the bushing insulation. These measurements allow for the estimation of relative dissipation factor change (Δtanδ) and relative capacitance change (ΔC/C₀).

Key Features:

- Monitoring of bushing capacitance and tanδ/power factor

- High-speed analog input channels

- Synchronous data acquisition

- Digital signal processing

- Adapters for various bushing tap designs

- RMS and peak voltage measurements

- Frequency and phase measurements

- User-configurable alarm settings

- Overvoltage monitoring

Modern power grids, incorporating high levels of renewable energy and HVDC technology, demand advanced monitoring devices to ensure reliability. Equipment in these grids frequently faces transient overvoltages from switching operations or lightning strikes, which can degrade insulation over time.

Continuous monitoring of transient overvoltages yields vital data on their frequency, amplitude, waveform characteristics, and origin. These overvoltages typically differ from standard test impulses used for insulation testing. By analyzing this real-world data, it is possible to assess their impact on transformer insulation systems, verify the effectiveness of surge protection devices, diagnose network faults, identify critical events, and make informed decisions for system planning. This includes customized insulation based on characteristic overvoltages, adjusting or installing additional surge arresters, and planning appropriate insulation levels.

Overvoltage measurement methods

The capacitive bushing can function as a capacitive voltage divider for measuring voltage transients. A special bushing tap adapter and measuring impedance are designed to accurately transfer the overvoltage amplitude and waveform to the low-voltage side. These components are part of the bushing sensor used for monitoring bushing capacitance and tanδ/power factor. Our system has been tested and verified for all standard waveform shapes, including switching, lightning, and chopped lightning waveforms.

The low-voltage output from the sensor is connected to the transient recorder module of Končar TMS. This system synchronously captures waveforms across all channels with a sampling rate of 4.5 MS/s and a recording duration of up to 7 seconds.

Overvoltage analysis

A wealth of data can be extracted from the database of measured overvoltages. The Frequency Domain Severity Factor (FDSF) is used to detect severe overvoltages. FDSF compares the frequency spectrum of the measured waveshape with the impulse test waveshape envelope. If the factor exceeds 1, it indicates that the transformer has not been tested for such waveshapes. It is important to note that although the transformer may not have been tested for a specific waveshape, it does not necessarily mean it cannot withstand it.

Alongside FDSF, parameters such as amplitude, rise time, tail time, and main oscillation frequency are observed and statistically analyzed. Overall, statistical analysis of actual overvoltage waveshapes in the power grid can provide valuable insights into overvoltage phenomena. Information on real overvoltages is crucial for improving transformer design and testing, allowing for tailored specifications based on the transformer's installation location.

Partial discharge monitoring

Partial discharges are the earliest indicators of insulation degradation or defects in transformers, generators, motors, and cables. Detecting and monitoring these signs of impending failure allows for proactive maintenance planning, helping to prevent catastrophic events.

Insulation failures can often lead to fires or explosions, causing substantial damage to primary equipment and surrounding structures. Such incidents result in high costs due to asset damage and decreased availability. Asset managers strive to minimize these risks and keep maintenance expenses as low as possible.

Končar TMS provides detailed insights into the condition of insulation by measuring partial discharges. Equipped with a comprehensive range of accessories and sensors, it can measure across various types of equipment. Its advanced processing algorithms ensure reliable measurement results and unparalleled real-time processing performance.

Key Features include fully synchronous high-speed acquisition, wide input range, adjustable digital filters, smart self-adjustable gain control with 15 levels.

Additionally, it includes automatic noise suppression, automatic classification of partial discharges, and real-time processing of up to 2,000,000 pulses per channel. This system features an intuitive user interface, offers a unique solution for every type of equipment, and complies with IEC and IEEE standards.