Shaft Current and Voltage Protection – SCVP

Electrical rotating machines must meet the increasing demands of power systems while optimizing power generation. Failures or unplanned downtime can lead to significant material damage. Implementing various monitoring and protection methods for rotating machines can mitigate or even prevent such events. These methods enhance asset management, extend machine life, and reduce costs associated with unplanned downtimes and unnecessary maintenance.

Due to the asymmetry of the magnetic field in rotating machines, a voltage can be induced in the shaft, varying in amplitude and frequency based on the machine's type, size, and load. The low impedance of the circuit, comprising the shaft, bearings, oil film, and other structural components, can cause shaft current flow, leading to bearing damage.

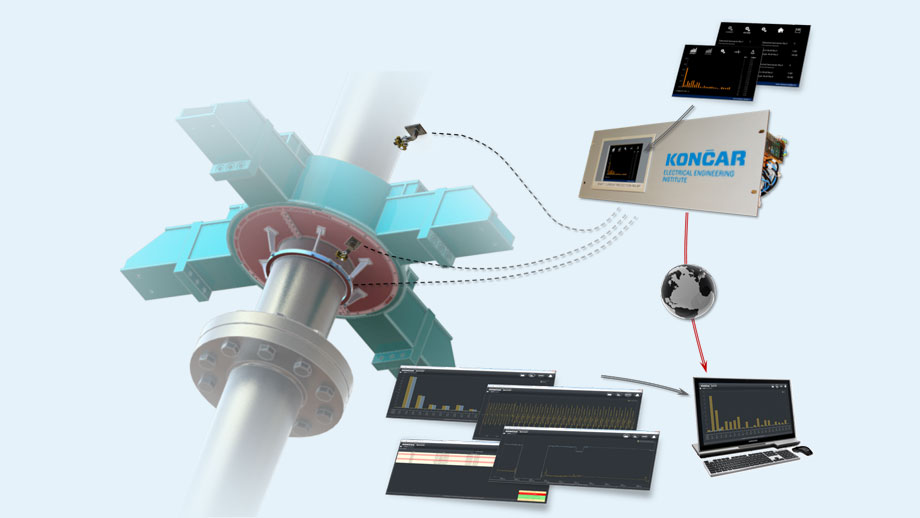

The Shaft Current and Voltage Protection (SCVP) system measures and analyzes shaft voltage and current that can damage generator bearings.

The key features of the SCVP system include online data analysis, protection configuration based on harmonic composition, database creation (trends, waveforms, alarms), and the ability to access the application locally or remotely.

Detailed analysis of measured data can pinpoint the causes of shaft currents and voltages. The primary purpose of the SCVP system is to detect these currents and voltages, which can damage generator bearings, thereby preventing significant economic losses.

Depending on the chosen type of SCVP, users can access measurement data via a local touchscreen display (local HMI) and through a web server (web application). Local visualization provides real-time data, waveforms, and spectra. All screens can be customized to meet customer requirements, including the native language.

The SCVP system includes a multi-user web server that enables remote access and an overview of all system data via a standard web browser. This web server allows access to the SCVP system from any desktop or laptop computer (running Windows or macOS), tablet (iOS or Android), or smartphone (iOS or Android).

System access is available without needing to install additional software, using standard web browsers such as Google Chrome, Internet Explorer, Mozilla Firefox, or Safari. The web server provides insight into real-time data, vibration spectra, trends, waveforms, alarms, and other diagnostic tools. For SCVP variants with a database, trends and waveforms are also available.

Advantages of the SCVP system include:

- System implementation with minimal interference in machine operation and seamless integration with other systems (e.g., SCADA)

- Web integration into a single access point, enabling the monitoring of critical equipment across multiple power plants

- User-friendly interface, providing intuitive data presentation and remote access via standard web browsers

- Online analysis for reliable predictive monitoring

- Spectral analysis (FFT) of the measured signal, allowing for custom alarm settings for critical values

- Long-term data storage and historical value archives for comprehensive analyses

The SCVP system has been deployed in numerous hydro and turbo generators worldwide. Our customers acknowledge its value and importance in monitoring one of the most critical issues faced during generator operation.